CLOSE

About Elements

田中贵金属是贵金属领域的翘楚企业。

支撑社会发展的先进素材和解决方案、

创造了这些的开发故事、技术人员们的心声、以及经营理念和愿景——

Elements是以“探求贵金属的极致”为标语,

为促进实现更加美好的社会和富饶的地球未来传播洞察的网络媒体。

Next generation flexible thin metal film based electrodes

Flexible electrodes, electronic components that conduct electricity, are of key importance for the development of numerous wearable technologies, including smartwatches, fitness trackers and health monitoring devices. Ideally, electrodes inside wearable devices should retain their electrical conductance when they are stretched or deformed.

Many flexible electrodes developed so far are made of metal thin films placed on elastic substrates. While some of these electrodes are flexible and conduct electricity well, sometimes, the metal films are fractured, which can result in sudden electricity disconnection.

Researchers at University of Illinois at Urbana-Champaign have recently introduced a new design that could enable the development of strain-resilient flexible electrodes that conduct electricity well, even when they are stretched or deformed. This design, outlined in a paper published in Nature Electronics, involves the introduction of a thin, two-dimensional (2-D) interlayer, which reduces the risk of fractures and retains electrical connections of metal films.

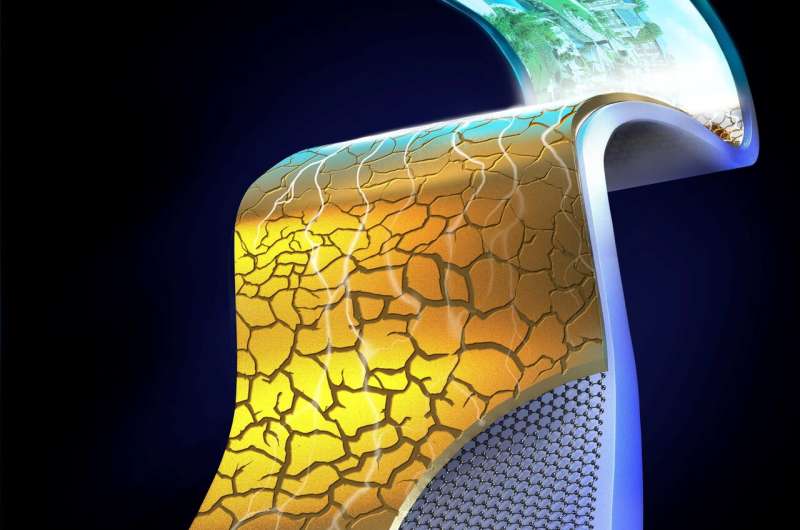

Artistic conceptual image of the researchers’ work showing 2D interlayer enabled delayed/tortuous cracking of metal thin-films and an image of a metal-2D interconnector integrated flexible light-emitting device.

Credit: Cho et al.

“We were interested in addressing outstanding unmet challenge of unexpected, complete electrical disconnection of flexible electrodes that is commonly observed after the onset of inevitable mechanical fracture during their use, which severely limits the functional lifespan of flexible/wearable electronics,” SungWoo Nam, one of the researchers who carried out the study, told TechXplore. “Our work showed the elongated conductance of a metal thin film itself with strain (termed ‘electrical ductility’ in analogy to mechanical ductility, which describes elongation of deformation with strain) for the first time, by changing fracture behaviors of the metal film with the underlying 2-D-interlayers.”

Nam and his colleagues found that inserting an atomically thin 2-D interlayer, such as graphene, into thin-film metal electrodes, reduced the risk of fractures and increased the electrode’s ability to conduct electricity under varying degrees of strain, which they refer to as its electrical ductility. This occurs because strong and weak van der Waals interactions in the 2-D materials induce a unique buckling deformation that delays damages to the electrodes’ metal thin films.

“The resulting ‘controlled’ cracking of the metal thin films enables substantially enhanced/robust electrical conduction,” Nam said. “Our 2-D-interlayer approach is not limited to certain combinations of metals and 2-D materials, but rather, it highlights different practical strategies to enhance the electromechanical reliability of various metal-based elements utilized in current wearable electronics applications, which could have a positive impact for the wearable electronics industry.”

The design introduced by Nam and his colleagues can be applied to a wide range of electrodes based on thin metal films. In their study, the researchers demonstrated the feasibility of their approach by using it to create a flexible electroluminescent light-emitting diode (LED) device. Remarkably, they found that their strategy can substantially improve the electromechanical robustness of commonly used electrodes (i.e., with its resistance decreased by several orders of magnitude and an extended region of stable resistance) under multimodal deformation.

In the future, this work could have significant implications for the development of new electronics. More specifically, their new electrode design could be used to fabricate a wide range of more resistant and better performing wearable devices.

“People working on flexible/wearable electronics with metal film based electrical components, such as flexible electrodes and interconnects, might be particularly interested in our findings,” Nam said. “We are interested in expanding our concept to various other conducting materials as well as investigating the scalability of our approach and its potential impact on flexible/wearable electronics.”

More information: Strain-resilient electrical functionality in thin-film metal electrodes using two-dimensional interlayers. Nature Electronics(2021). DOI: 10.1038/s41928-021-00538-4.

© 2021 Science X Network

Citation: A design to improve the resilience and electrical performance thin metal film based electrodes (2021, March 1) retrieved 1 March 2021 from https://techxplore.com/news/2021-03-resilience-electrical-thin-metal-based.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.

This article was from Tech Xplore and was legally licensed through the Industry Dive publisher network. Please direct all licensing questions to legal@industrydive.com.

![]()