CLOSE

About Elements

田中贵金属是贵金属领域的翘楚企业。

支撑社会发展的先进素材和解决方案、

创造了这些的开发故事、技术人员们的心声、以及经营理念和愿景——

Elements是以“探求贵金属的极致”为标语,

为促进实现更加美好的社会和富饶的地球未来传播洞察的网络媒体。

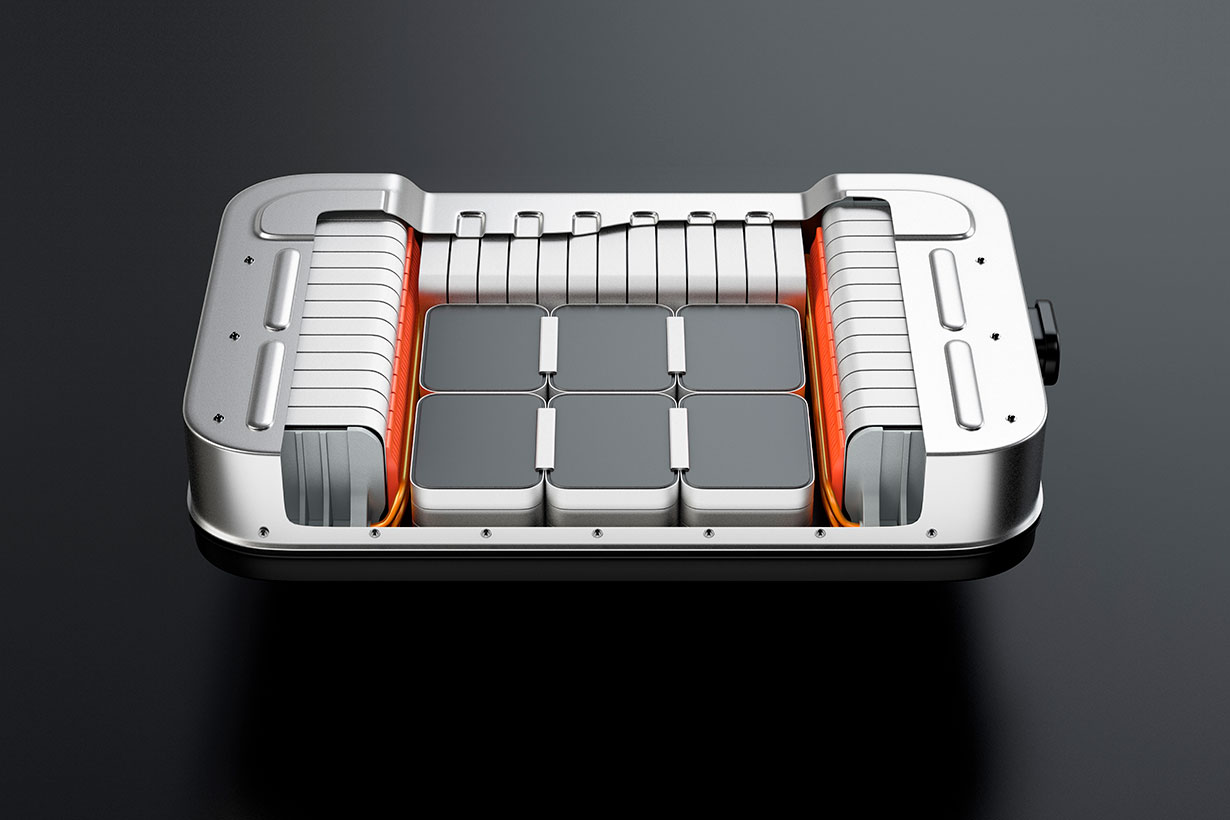

Electric vehicle batteries could get big boost with new polymer coating

Scientists at Lawrence Berkeley National Laboratory (Berkeley Lab) have developed a conductive polymer coating – called HOS-PFM – that could enable longer lasting, more powerful lithium-ion batteries for electric vehicles.

“The advance opens up a new approach to developing EV batteries that are more affordable and easy to manufacture,” said Gao Liu, a senior scientist in Berkeley Lab’s Energy Technologies Area.

The HOS-PFM coating conducts both electrons and ions at the same time. This ensures battery stability and high charge/discharge rates while enhancing battery life. The coating also shows promise as a battery adhesive that could extend the lifetime of a lithium-ion battery from an average of 10 years to about 15 years, Liu added.

To demonstrate HOS-PFM’s superior conductive and adhesive properties, Liu and his team coated aluminum and silicon electrodes with HOS-PFM, and tested their performance in a lithium-ion battery setup.

The HOS-PFM conductive binder is made of a nontoxic polymer that transforms at the atomic level in response to heat. Before heating: At room temperature (20 degrees Celsius), alkyl end-chains (black squiggly lines) on the PFM polymer chain limit the movement of lithium ions (red circles). After heating: When heated to about 450 degrees Celsius (842 degrees Fahrenheit), the alkyl end-chains melt away, creating vacant “sticky” sites (blue wavy lines) that “grab” onto silicon or aluminum materials at the atomic level. PFM’s polymer chains then self-assemble into spaghetti-like strands called “hierarchically ordered structures” or HOS. Like an atomic expressway, the HOS-PFM strands allow lithium ions to hitch a ride with electrons (blue circles). These lithium ions and electrons move in synchronicity along the aligned conductive polymer chains. See GIF here (Credit: Jenny Nuss/Berkeley Lab)

Silicon and aluminum are promising electrode materials for lithium-ion batteries because of their potentially high energy storage capacity and lightweight profiles. But these cheap and abundant materials quickly wear down after multiple charge/discharge cycles.

During experiments at the Advanced Light Source and the Molecular Foundry, the researchers demonstrated that the HOS-PFM coating significantly prevents silicon- and aluminum-based electrodes from degrading during battery cycling while delivering high battery capacity over 300 cycles, a performance rate that’s on par with today’s state-of-the-art electrodes.

The results are impressive, Liu said, because silicon-based lithium-ion cells typically last for a limited number of charge/discharge cycles and calendar life. The researchers recently described these findings in the journal Nature Energy.

The HOS-PFM coating could allow the use of electrodes containing as much as 80% silicon. Such high silicon content could increase the energy density of lithium-ion batteries by at least 30%, Liu said. And because silicon is cheaper than graphite, the standard material for electrodes today, cheaper batteries could significantly increase the availability of entry-level electric vehicles, he added.

The team next plans to work with companies to scale up HOS-PFM for mass manufacturing.

Research Report:Formation of hierarchically ordered structures in conductive polymers to enhance the performances of lithium-ion batteries

This article was from SpaceDaily.com and was legally licensed through the Industry Dive Content Marketplace. Please direct all licensing questions to legal@industrydive.com.