CLOSE

About Elements

田中贵金属是贵金属领域的翘楚企业。

支撑社会发展的先进素材和解决方案、

创造了这些的开发故事、技术人员们的心声、以及经营理念和愿景——

Elements是以“探求贵金属的极致”为标语,

为促进实现更加美好的社会和富饶的地球未来传播洞察的网络媒体。

Why Making Computer Chips Has Become a New Global Arms Race

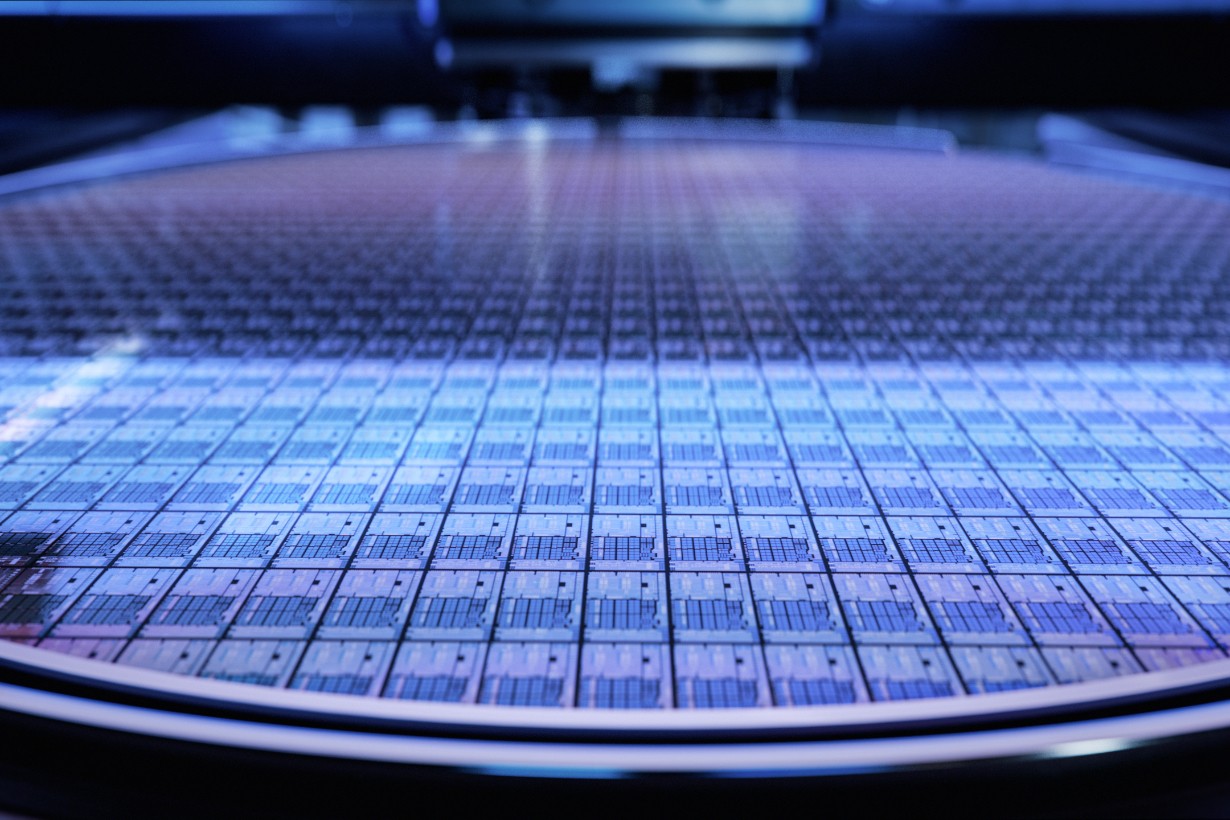

The incredibly complex, high-stakes business of making semiconductors has always been a battle of corporate giants. Now it’s also a race among governments. These critical bits of technology — also known as integrated circuits or, more commonly, just chips — may be the tiniest yet most exacting products ever manufactured. And because they’re so difficult and costly to produce, there’s a worldwide reliance on just a handful of companies, a dependence that was brought into stark relief by shortages during the pandemic. Access to chips has also become a geopolitical weapon, with the US ratcheting up curbs on exports to China to contain the rise of an economic rival.

1. Why the war over chips?

There’s silicon at the heart of every artificial intelligence breakthrough, range upgrade for electric vehicles or guidance system for hypersonic missiles. Most of the world’s leading chip technology originates in the US. China is the biggest market for the electronic components and has a growing desire to make more of the chips it uses itself. That’s made the industry a focal point for Washington as it tries to limit the rise of its Asian rival and address what it says are national security concerns. For its part Beijing has poured billions into efforts to build its own chip industry and lessen its reliance on imports that are increasingly subject to restrictions by the US. At the same time, Europe and the US are setting aside huge sums of government money to bring back physical production of chips, reducing what they say is a dangerous reliance on a few facilities in East Asia.

2. Why are chips so critical?

They’re what’s needed to process and understand the mountains of data that have come to rival oil as the lifeblood of the economy. Made from materials deposited on disks of silicon, chips can perform a variety of functions. Memory chips, which store data, are relatively simple and are traded like commodities. Logic chips, which run programs and act as the brains of a device, are more complex and expensive. Access to components such as Nvidia Corp.’s H100 AI accelerator has become linked to both national security and the fortunes of giant companies such as Alphabet Inc.’s Google and Microsoft Corp. as they race to build out giant data centers aimed at stealing the lead in what’s seen as the future of computing. But even every-day devices are increasingly reliant on chips. Every press of a button in a car full of gadgetry requires simple chips to translate that touch into electronic signals. And all battery-powered devices need chips to convert and regulate the flow of electricity.

3. Who controls supply?

Chipmaking has become an increasingly precarious and exclusive business. New plants have a price tag of more than $20 billion, take years to build and need to be run flat-out for 24 hours a day to turn a profit. The scale required has reduced the number of companies with leading-edge technology to just three — Taiwan Semiconductor Manufacturing Co. (TSMC), South Korea’s Samsung Electronics Co. and Intel Corp. of the US. TSMC and Samsung act as so-called foundries, providing outsourced manufacturing for companies around the world. Everyone from Nvidia to the internal efforts of Microsoft and Amazon are dependent on access to the best manufacturing, most of which is located in Taiwan. Intel used to focus on making chips for its own use, but is also now trying to compete with TSMC and Samsung for contract manufacturing business. Lower down the food chain there’s a huge industry that makes so-called analog chips. Companies such as Texas Instruments Inc and STMicroelectronics NV are leading makers of the components that control those button presses and convert power in devices. This is the area that China, blocked from access to many of the machines needed to make cutting edge parts, is targeting, investing heavily to boost production and grab market share.

4. What’s happening in the geopolitical competition?

Despite a huge Chinese spending spree, the country’s chipmakers still depend on US technology, and their access to overseas chip production technology is shrinking.

- The US imposed tighter export controls in 2023 on some chips and chipmaking equipment to stop China from developing capabilities that Washington regards as potential military threats, such as supercomputers and artificial intelligence. In October, the rules were tightened further and agreements reached with Japan and the Netherlands to follow suit were due to come into effect in 2024. Then, in early 2024, the US pressed allies to further tighten restrictions on China’s access to semiconductor technology, aiming at plugging holes in export controls. The Biden administration is trying to bring Germany and South Korea into a China chip curb agreement that already includes Japan and the Netherlands, since all four countries are home to key firms in the semiconductor supply chain.

- Some of China’s technology leaders, including Huawei Technologies Co, have been placed on the so-called entity list. American chip technology suppliers have to get US government approval to sell to these blacklisted companies, a step meant to limit China’s ability to develop high-end chips and build cutting-edge AI applications. But Huawei in 2023 announced the Mate 60 Pro phone powered by a new Kirin 9000s chip. That processor was made by Shanghai-based Semiconductor Manufacturing International Corp. with so-called 7-nanometer technology, more advanced than US rules allow.

- US politicians have decided that they need to do more than just hold back China. The 2022 Chips and Science Act will provide about $50 billion of federal money to support US production of semiconductors and foster the skilled workforce needed by the industry. TSMC, Samsung and Intel, the three biggest chipmakers, have all announced plans for new US plants.

- Europe has joined the race to reduce the concentration of production in East Asia. European Union nations agreed in November on a €43 billion ($46 billion) plan to jump-start their semiconductor output. The goal is to double production in the bloc to 20% of the global market by 2030.

- Japan has earmarked about ¥4 trillion ($26.7 billion) in government funds for revitalizing its semiconductor sector and hopes that spending in the field, including private sector support, can reach ¥10 trillion. Among the plan’s goals is the tripling of domestically produced chip sales by 2030.

5. How does Taiwan fit into all this?

The island democracy emerged as the dominant player in outsourced chipmaking partly because of a government decision in the 1970s to promote the electronics industry. TSMC almost single-handedly created the “foundry” business model — building chips designed by others. It’s an approach that chip users embraced as the cost of new plants skyrocketed. Big customers like Apple Inc. gave TSMC the massive volume to build industry-leading expertise, and now the world relies on it. The company overtook Intel in terms of revenue in 2022. Matching its scale and skills would take years and cost a fortune. Politics have made the race about more than money, though, with the US signaling it will continue efforts to restrict China’s access to American-designed chips made in Taiwan’s foundries. China has long claimed the island, just 100 miles off its coast, as its own territory and threatened to invade to prevent its formal independence.

This article was written by Debby Wu and Ian King from Bloomberg and was legally licensed through the DiveMarketplace by Industry Dive. Please direct all licensing questions to legal@industrydive.com.

Related Information

Technology Trend and Advanced Packaging Material for Power Device

Power device is key component for a wide range of applications such as smartphones, electronic devices, next-generation mobility including EV and HEV, cellular base stations, power control for renewable energy and so on. Its technology development is thriving day by day.

We introduce advanced packaging technology trends and cutting-edge materials designed to address challenges such as high heat dissipation, high heat resistance, reliable bonding in manufacturing, and miniaturization.

![]()