CLOSE

About Elements

为了美好的未来,

传播支撑社会的科技

TANAKA是“贵金属”的专家,为世界提供创造“社会价值”的“制造”。

“Elements”是主要提供符合我们的业务及价值观的有关“科技”和“可持续发展”

等方面信息的网络媒体。

在急速发生范式转换的现代,我们将不断传播促进实现更加美好的“社会”和富饶“地球”的未来的启示。

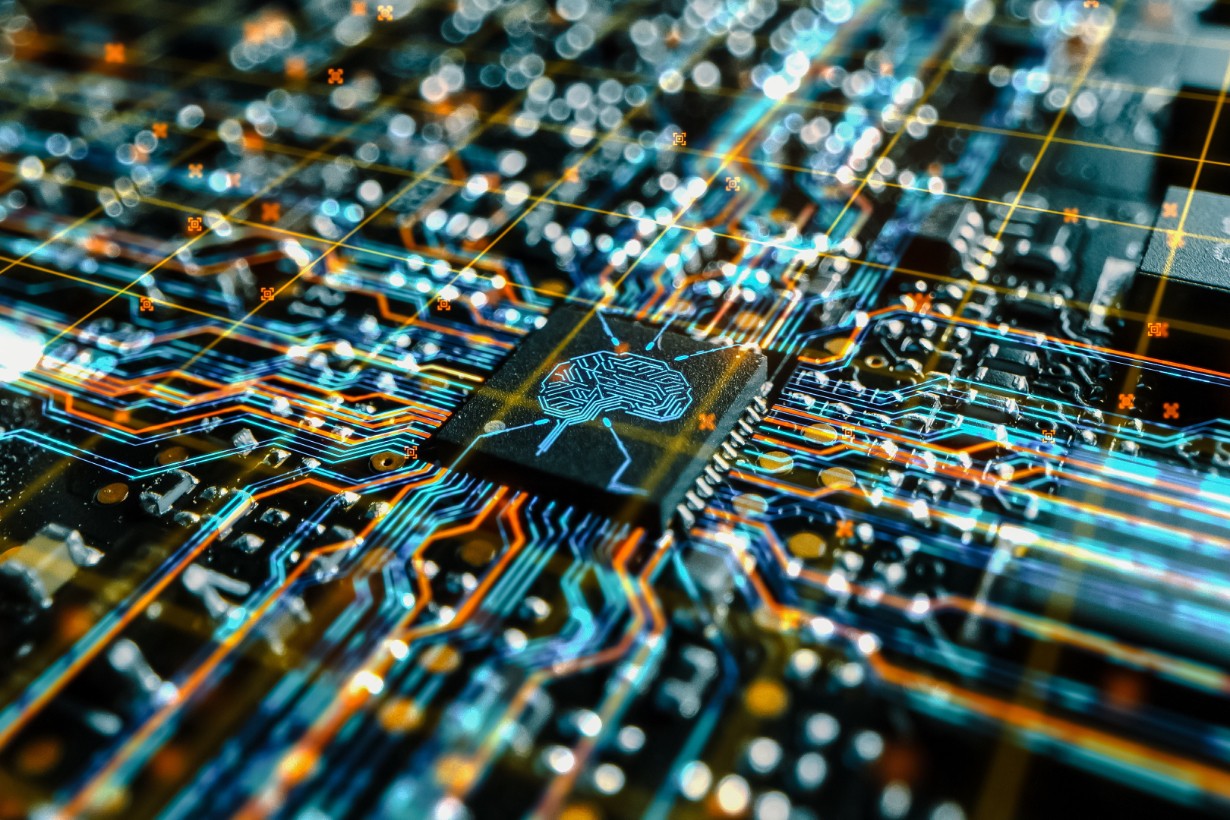

Apple and Tesla Veterans Aim to Help Japan Design AI Chips

The Japan government-backed research group developing semiconductors will partner with US startup Tenstorrent Inc. on the design of its first advanced AI chip.

Tenstorrent, led by Tesla Inc. and Apple Inc. veteran Jim Keller, will license its design for part of Japan’s artificial intelligence accelerator and also co-design the overall chip, the US company said at a joint event in Tokyo on Tuesday. Working with the open-source RISC-V standard, Tenstorrent aims to provide customers with an alternative to the leaders Nvidia Corp. and Arm Holdings Plc, who have their own so-called instruction sets to communicate between hardware and software.

The Japanese government is funding a range of projects from research to advanced chip manufacturing, making an ambitious $67 billion bid to reclaim a central role in the semiconductor industry. The Tenstorrent agreement has the potential to advance those efforts, with the goal of producing the jointly designed AI chips at the government-backed startup Rapidus Corp.

“Concerns around AI using up all the electricity in the world make technology to decrease power consumption important,” said Rapidus Chief Executive Officer Atsuyoshi Koike at the event alongside Tenstorrent CEO Keller. “With Tenstorrent, we hope to launch AI accelerators at the fastest time-to-market rate.”

The 18-month-old company is aiming to begin chip production in 2027 in competition with leaders Taiwan Semiconductor Manufacturing Co. and Samsung Electronics Co. But Rapidus will need customers for its facility and Keller’s team sees Japan working to ensure both supply and demand.

“What Japan is doing is they recognize that you can’t just build a fab and hope,” David Bennett, chief customer officer of Tenstorrent, said in an interview. “So they’re taking large investments to make sure that they’re filling this fab. So what you see today is really the first one.”

Bennett said that Tenstorrent has “line of sight to hundreds of millions of dollars of business in Japan” and is working closely with the Japanese government and corporations. His firm presently has 400 employees across the US, Canada, Serbia, India, South Korea and Japan. Tenstorrent is also in close contact with the US government to ensure it’s in full compliance with Washington’s technology export controls.

Beside Keller, Tenstorrent has Keith Witek, who spent 13 years at Advanced Micro Devices Inc., as its chief operating officer and Wei-han Lien as its chief chip architect. Lien led Apple’s work on advancing its in-house chip design, which has grown from powering the iPhone to also running its iPads and even desktop Mac computers.

In Japan, the company will work on AI chip designs with the government research group, known as Leading-edge Semiconductor Technology Center or LSTC.

Still, production in Japan may be a challenge. Rapidus’ goal of manufacturing state-of-the-art, 2-nanometer logic chips by 2027 is considered something of a long shot.

Japan’s LSTC will pursue and promote AI tech dedicated to “edge inference processing applications, including generative AI, through international collaboration,” its chairman, Tetsuro Higashi, said in the announcement. The country has managed to attract many of its semiconductor experts who’d gone to work overseas back, Bennett said, as it works to bolster its expertise.

This article was written by Vlad Savov and Jane Lanhee Lee from Bloomberg and was legally licensed through the DiveMarketplace by Industry Dive. Please direct all licensing questions to legal@industrydive.com.

Related Information

Technology Trend and Advanced Packaging Material for Power Device

Power device is key component for a wide range of applications such as smartphones, electronic devices, next-generation mobility including EV and HEV, cellular base stations, power control for renewable energy and so on. Its technology development is thriving day by day.

We introduce advanced packaging technology trends and cutting-edge materials designed to address challenges such as high heat dissipation, high heat resistance, reliable bonding in manufacturing, and miniaturization.

![]()