Used in LEDs since the 1990s, it is known for its robust, hexagonal crystal structure and can handle larger electric fields in a compact form factor compared to silicon, enabling faster switching.

Apple’s first GaN charger was for the 16-inch MacBook Pro in 2021, and if you own an iPhone 15, you’re likely using a GaN charger.

Measuring conditions inside a reactor

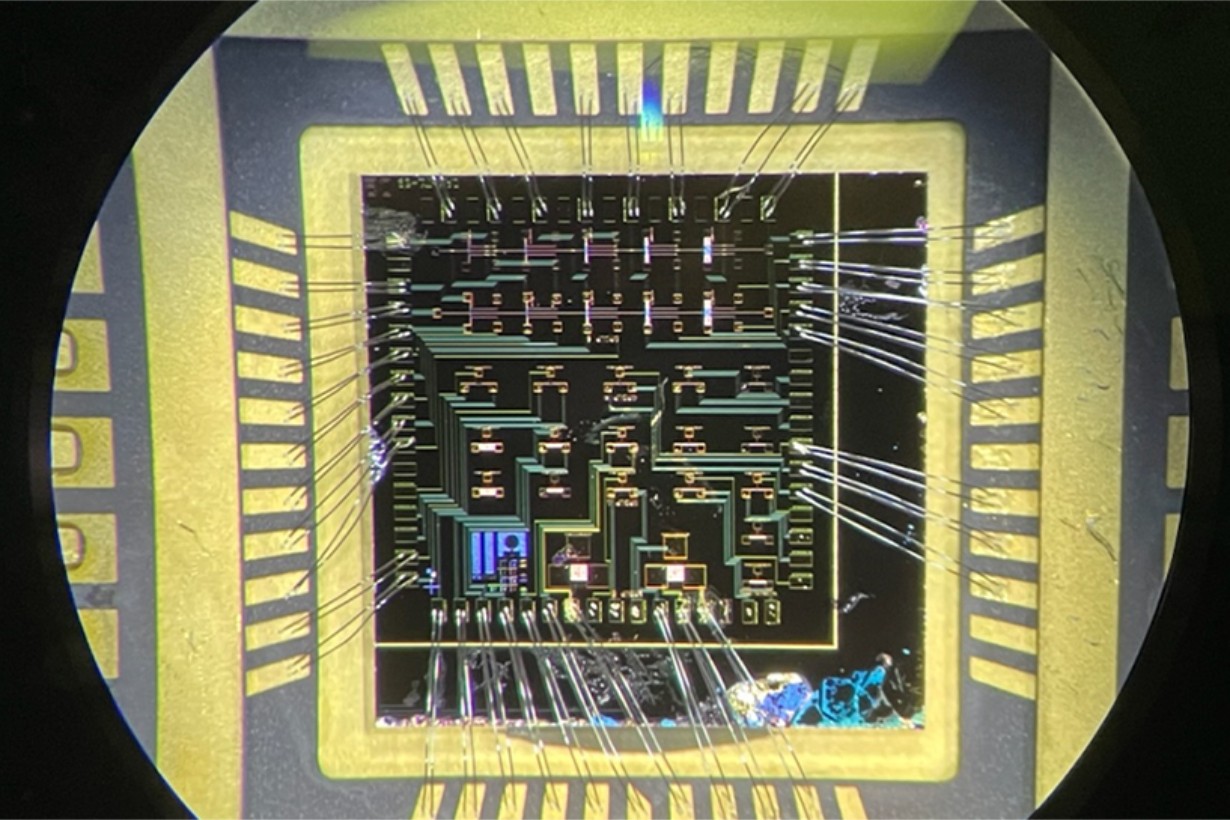

It turns out that GaN could be even more impressive than previously thought. Sensors used to monitor a nuclear reactor’s cooling system typically struggle with accuracy due to radiation. Researchers from the Department of Energy’s Oak Ridge National Laboratory (ORNL) discovered that combining the sensors with high-performance electronics made from GaN solved the problem.

ORNL’s materials science team found a GaN transistor maintained operations near the core of a nuclear reactor at The Ohio State University. “We are showing it is great for this neutron environment,” said Kyle Reed, lead researcher at ORNL. This advancement is significant for nuclear facilities where early condition monitoring can prevent equipment failure and reactor downtime.

Current sensor data processing relies on silicon-based electronics connected by long cables, introducing noise and reducing accuracy. “Our work makes measuring conditions inside an operating nuclear reactor more robust and accurate,” Reed noted.

Researchers at ORNL irradiated GaN transistors for three days at temperatures up to 125 degrees Celsius. Remarkably, they endured the conditions, handling at least 100 times the radiation dose that standard silicon devices could withstand.

Microreactors, which generate smaller power outputs but require compact, resilient components, could benefit from GaN transistors, potentially being deployed to sites like military bases or disaster zones.

Despite being commercially available for about a decade, GaN has untapped potential. “We’re opening up different side avenues for using gallium nitride, so we can start to create a more reasonable market demand for investment, research and workforce development for subclasses of electronics beyond consumer-grade,” Reed said.

※Top Image: Kyle Reed/ORNL, U.S. Dept. of Energy

This article was written by Wayne Williams from TechRadar and was legally licensed through the DiveMarketplace by Industry Dive. Please direct all licensing questions to legal@industrydive.com.