CLOSE

About Elements

田中贵金属是贵金属领域的翘楚企业。

支撑社会发展的先进素材和解决方案、

创造了这些的开发故事、技术人员们的心声、以及经营理念和愿景——

Elements是以“探求贵金属的极致”为标语,

为促进实现更加美好的社会和富饶的地球未来传播洞察的网络媒体。

Material innovation: The new frontier of industrial automation

Source: Asia Pacific Metalworking Equipment News | Manufacturing | Automation

Date: February 06, 2026

Link: Material innovation: The new frontier of industrial automation – Asia Pacific Metalworking Equipment News | Manufacturing | Automation | Quality Control

Material innovation: The new frontier of industrial automation

By Yasutaka IHARA, Director & Corporate Officer, TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd.

Industrial automation has always been about making communication seamless between production, management, supply chains, and customer service via data and analytics. Now, with the rise of artificial intelligence (AI) that objective is accelerating.

This could not have come at a more opportune time, as manufacturers face growing pressures to maximise uptime, navigate supply chain volatility, and optimise energy efficiency.

Today, AI chips are already helping solve the following problems in smart factories:

- Downtime and maintenance costs: AI-powered predictive maintenance helps anticipate equipment failures before they occur, reducing costly unplanned downtime.

- Energy inefficiency: Intelligent power management systems optimise energy consumption across facilities, lowering operational costs and environmental impact.

- Space and system complexity: Miniaturised control systems integrate multiple functions into compact modules, enabling smarter, more flexible production lines.

- Quality assurance: Machine vision and real-time analytics improve defect detection and process optimisation, enhancing product quality and consistency.

- Supply chain fragility: AI-driven logistics and planning tools help manufacturers respond to disruptions with agility and precision.

These advancements highlight that AI capabilities are fast becoming a must-have, and manufacturers in Asia Pacific would do well to map out an adoption plan. The region has lofty ambitions of becoming a hub for advanced manufacturing and innovation; and while AI can elevate robotics and drive smart automation, it isn’t some bolt-on solution with no shortcomings. The question is how can manufacturers truly utilise AI in a human-centric and sustainable way to create resilient industrial ecosystems.

Precious metals: The unsung hero

AI runs on next-generation processor chips that are designed to power predictive analytics, autonomous systems and real-time control. However, these chips need to perform reliably under extreme conditions, with minimal energy loss and maximum thermal stability.

These requirements are not conducive to the AI-led evolution of smart manufacturing. To work around that problem, we will need to deep dive into what powers the performance of these chips and the business outcomes they enable. That is something far less visible: the materials they’re built with.

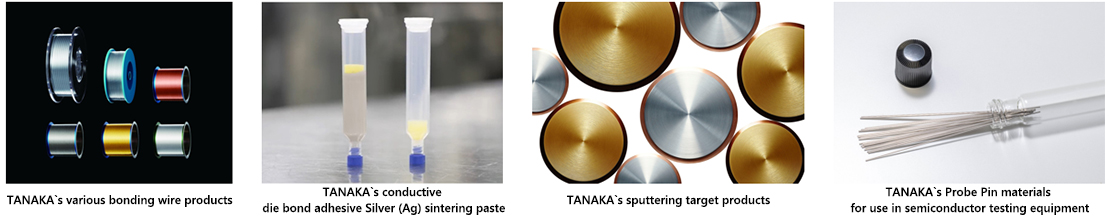

To meet these demands, chip designers rely on materials with exceptional conductivity, resistance to corrosion, and nanoscale precision. These are qualities found in precious metals such as gold, platinum, palladium and silver.

These metals are essential for wire bonding, sintering, thin-film formation and thermal management. As chip architectures grow more complex, the purity and efficiency of these materials become ever more mission critical.

However, further compounding the problem is that these metals are finite, expensive and scarce, requiring recycling technologies and a robust circular economy framework.

Innovation in materials science: An imperative for functional materials

The industry must therefore treat precious metals innovation as a priority, recognizing precious metals as essential functional materials and advancing both reduced-metal-content technologies and comprehensive recycling. Advances in bonding technologies, sintering pastes and thin-film deposition are enabling chips to perform better while using fewer resources.

For example, silver-based sintering materials support high-efficiency gallium nitride (GaN) devices used in AI servers and edge computing. Sheet-type bonding materials like AgSn TLP sheets offer large-area die attachment and superior heat dissipation – critical for high-power semiconductor packages.

These innovations are necessary due to the scarcity of precious metals. By improving thermal performance and bonding reliability, we extend the life of chips and reduce the need for new metals.

This article was reprinted from an article published in “Asia Pacific Metalworking Equipment News” on February 06, 2026, with permission from Asia Pacific Metalworking Equipment News.

This article was translated by TANAKA from Asia Pacific Metalworking Equipment News with their permission.

This article was published on Asia Pacific Metalworking Equipment News | Manufacturing | Automation.

Further information can be found here:

Learn more… (Asia Pacific Metalworking Equipment News)

Image reference: TANAKA to Showcase Advanced Semiconductor Materials in its Inaugural Participation at SEMICON India 2025 | TANAKA

Related Information